Industrial robots have revolutionized the industrial workplace across industries since their introduction into the manufacturing landscape. Most tasks regarded as too risky, tedious, repetitive, or dull for human workers can now be assigned to robots.

Robotic end arms are programmed to carry out tasks such as sorting, packing, and counting. They can perform these tasks at a faster rate and with high efficiency. Due to their increased demand and varying uses, robotic arm companies like EVSint.com are coming up with more advanced robots, and the manufacturing industries such as the automobile industry have benefited from these advancements.

By applying robotic end arms into the production line, it has become easier to produce more within a short period due to the enhanced efficiency. Outlined below are some ways in which robotic end arms have been applied in industries:

Page Contents

1. Adhesive Sealing, and Gluing

Robots are designed with numerous configurations that enable them to perform these tasks on the desired type of product. They can carry these tasks with great consistency thus ensuring uniformity in the end product. They can be programmed to make precise measurements and apply them in exact proportions.

2. Machine Tending

Robotic automation for a machine is the process of loading and unloading raw material into machinery for manufacturing processing. Robotics also take the role of overseeing the machine as it carries out these tasks. These benefits the company as it saves on the cost of hiring human workers.

3. Painting and Spraying

Robots are particularly used in automotive industries to apply paints. Painting work carried out by robots is consistent and of the highest quality. Some paints can be hazardous healthwise if inhaled for a prolonged duration of time by human workers. This makes robots the ideal alternative for carrying out these tasks. They also help in cutting down operational costs as more work is carried out in the shortest time possible. Some robots also use a precision-guided system which ensures there’s very little wastage.

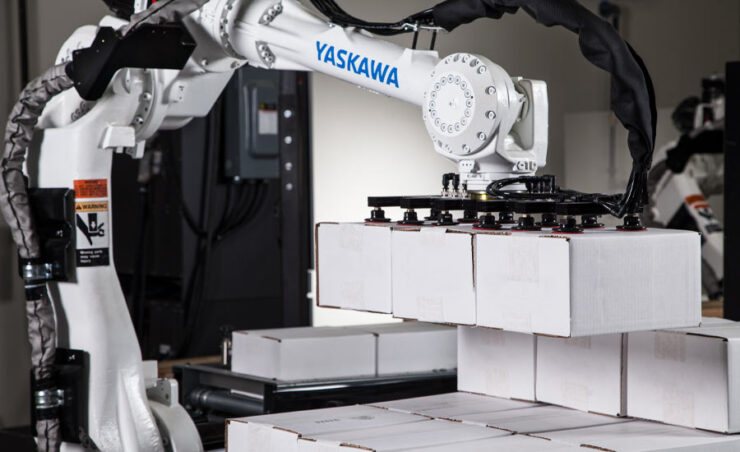

4. Picking, Packing, and Palletizing

An item in the production line often goes through multiple processes before its ready for shipping to the final consumer. The robotic end arm is highly specialized to handle these items all along the production line efficiently. Product damage during handling is also reduced to the minimum. Production cost and time are also significantly reduced. Additionally, one robot can carry out multiple tasks at a faster speed compared to several workers.

5. Assembly

The task of assembling is highly repetitive and tedious for human workers. But robots can perform these tasks over and over again at high speed without the need for breaks or rest. The final product is flawless. This kind of robotic end arms are most common in automobile and electrical product manufacturing companies. A sequence is installed in the memory of the robot which enables it to carry out the same action over and over again.

6. Agriculture

Robotic application in the agriculture industry today is widespread. Large farms extensively use automated machines to carry out tasks such as soil monitoring, sorting seedlings weeding, pruning, spraying, watering, and harvesting farm produce. Robotics is also used in animal keeping for tasks such as castrating, feeding, cleaning, egg collection, and sorting.

7. Arc Welding

Arc welding is the process of using intense heat to melt a joint causing it to intermix and join. A high heat torch at the end of the robotic arm melts the metal for the process to take place. Arc welding poses the risk of getting burnt, toxic gases are also emitted and they pose a health risk to the personS involved. Having a robot carry out the task saves them from these health hazards.

8. Food Processing

The adoption of robots in the process of handling and packing food is currently on the rise. This is due to the advantages that come with applying them in the process. Automation ensures that there is no process interruption hence increasing productivity. Robots are very fast and precise and product quality is raised. Robots are also be used for product sorting and removing unwanted materials

9. Product Testing

Robots are used to test products that would be either too risky or hard to do by a human worker. This includes products with explosive capabilities or dangerous chemicals. This ensures workers safety is guaranteed while working with these products

10. Pick and place for printed circuit board

Mounting components on the surface of the printed circuit board is impossible by human hands. Owing to the small working surface area and the high precision required. Pick and place robots come in handy for this type of task. they can place these components accurately, quickly, and repeatedly. The pick and place machines are fed with the information about component positions so that they know where to place them on the board. These settings are developed straight from the printed circuit board design information.

Conclusion

Robots have become an essential part of modern industries. Some things that had been impossible to do in the past due to human limitation can now be realized thanks to robots. More can be produced in a short time than would have been possible in the past. Qualities previously unattainable are now a reality. And as more and more improvements are made each day, the robotic industry is bound to get better and better. Artificial intelligence will give rise to more intelligent robots that will perform highly complex tasks.